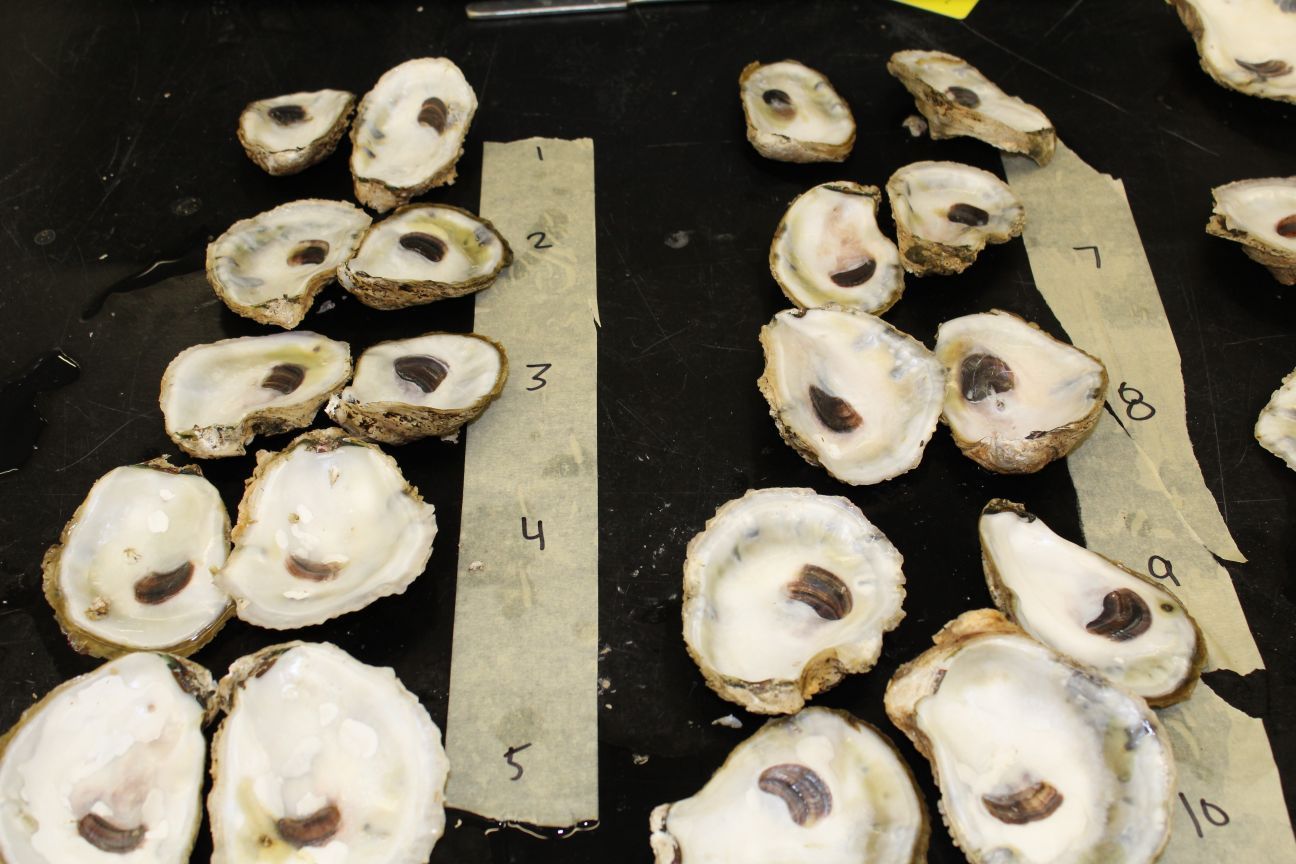

Moreover, various diets should be provided to ensure balanced food intake. maxima spat could be optimized by extending the nurture period in the hatchery. These results suggest that seed production of P. However, survival rate of spat was greater in the hatchery than in the sea. Spat held in the sea had greater shell length growth than those held in the hatchery. Spat reared on a medium ration (4.0 × 10 4 cells/mL/day) had greater shell length growth than those reared at high (8.0 × 10 4 cells/mL/day) and low (2.0 × 10 4 cells/mL/day) rations. Spat fed on a single diet ( Chlorella) had poorer shell length growth than those fed on diets composed of more than one species. Spat reared at high salinities (30 and 27) showed larger shell length growth and greater survival than those at low salinities (24 and 21). Growth declined with decrease in salinity. Salinity and rearing site also had significant effects on survival, but no significant differences were observed in terms of survival between the diet and diet availability treatments. Results showed that environmental conditions exerted significant effects on the growth of P. subcordiformis/50% Chlorella), diet availability (high, medium and low), and rearing site (hatchery and sea) on the growth and survival of pearl oyster Pinctada maxima spat. They are then considered to be competent for metamorphosis, ready for the setting phase.To understand the influences of environmental conditions on the performance of pearl oyster spat, we conducted four experiments to evaluate separately the effects of salinity (21, 24, 27, and 30), diet ( Isochrysis zhanjiangensis, Platymonas subcordiformis, Chlorella 50% I. When they reach a size of 250 microns, the larvae become eyed, going from the veliger stage to the pediveliger stage. The water is then changed and feeding is carried out on a daily basis with the different species of phytoplankton specified above. The larvae are regularly harvested on sieves of increasing size to check their growth and separate the biggest from the smallest. The resulting larvae then spend around twenty days growing. In triploid spawning, the eggs are crossed with sperm taken from tetraploid males supplied by IFREMER.Ģ4 hours after fertilisation, the larvae have usually gone from the trochophore stage to the "D"-larva stage (they are D-shaped). In diploid spawning, the eggs are mixed with the sperm taken from our diploid males. Individual sex is then determined by observation under the microscope and the females are separated from the males. With the latter technique, gametes (sperm and eggs) are obtained by gonad laceration. In the former technique, mature broodstock is placed into small individual spawning units and subjected to a number of shocks to stimulate the spontaneous release of gametes. Spawning can be induced by thermal shock or scarification. After a few days, the algae cells have multiplied and the operation is repeated until enough has been produced to feed the stock. The production process is sequential : every day a small volume of culture, known as inoculum, is diluted in a greater volume of well water. They are filter feeders, which means that they obtain their food by filtering water. Feed microalgae can either be produced inside lit, temperature-controlled rooms or in outdoor ponds exposed to sunlight. Oysters eat phytoplankton or small bits of algae suspended in the water. The phytoplankton used to feed the broodstock and larvae is grown using a variety of methods depending on the species. Tetraploid broodstock is produced and kept by IFREMER and its supply for the production of triploid spat is tightly controlled and secure. Each batch is cleaned and fed every day with various species of phytoplankton. In the event of losses or poor analysis results, the batch is discarded. All the batches are monitored and analysed in order to ensure they are healthy from the start. Hot temperature conditions accelerate maturity at the start of the spawning season and colder conditions slow down the maturation process until the start of the autumn. It is thus possible to have spawning throughout the year by adapting the temperature and quantity of food. This staggered approach enables us to prepare mature oysters from January through to September.

Once selected, these adult oysters are carefully cleaned and placed in rearing tanks on a two-monthly basis, from November to July. The activities that take place in this unit can be split into three categories: broodstock maturation, the production of phytoplankton and larval growth.įor several years now, diploid broodstock has been selected on the basis of origin and overall performance in terms of growth, shape, robustness, etc. The seawater used is filtered and purified on-site. This first phase takes place in controlled conditions in a purpose-built facility.

The oyster hatchery represents the first phase in the oyster spat production process.

0 kommentar(er)

0 kommentar(er)